What is a supplier audit?

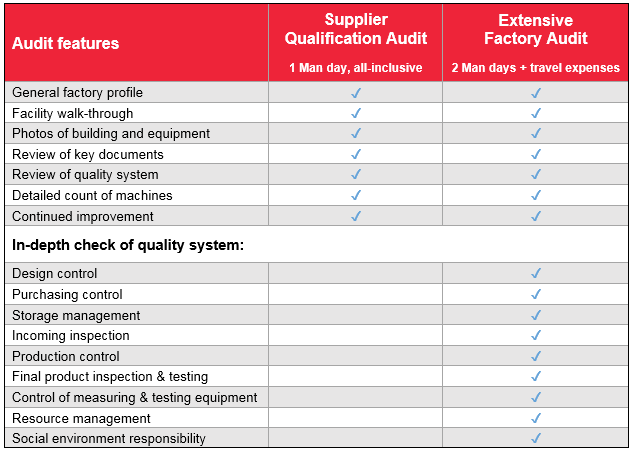

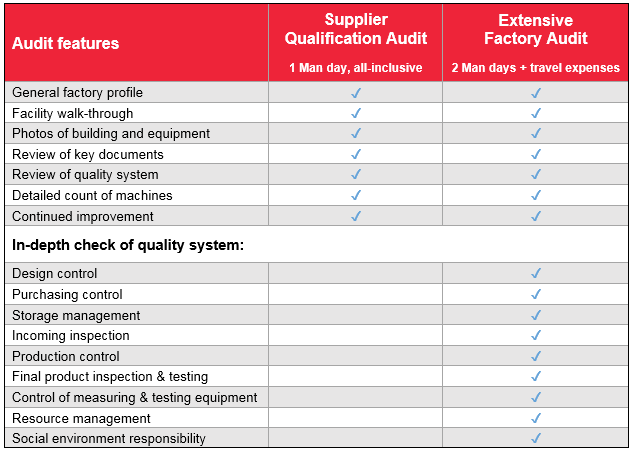

AQF offers two supplier audit services – a simplified Supplier Qualification Audit and an Extensive Factory Audit.

A supplier qualification audit is often adequate for importers who just want to see a broad overview of their supplier’s facility. It offers insight into general supplier information, necessary licenses, employee relations, organizational structure and basic facilities and production equipment.

But when you need a more thorough audit, you’ll benefit from AQF’s extensive factory audit. An extensive factory audit includes all of the same checks as a supplier qualification audit, as well as an in-depth check of the factory’s quality management system.

Tailored supplier audit reports

We can customize evaluations to answer specific concerns you may have and look more closely at specific areas of the factory that are critical to your project. A supplier audit may also include meetings with factory management to explain industry best practices or product characteristics and obtain feedback.

AQF reporting covers exactly what you need to know in order to make informed decisions about using a particular supplier. AQF staff will also review the findings with your team in detail and assist you with any follow-up questions you may have.